P200 platform propulsion STM

Activities: Structural & Thermal engineering

Customer: Bradford Space

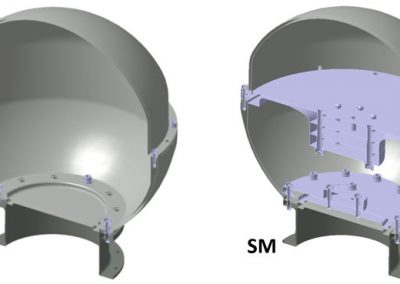

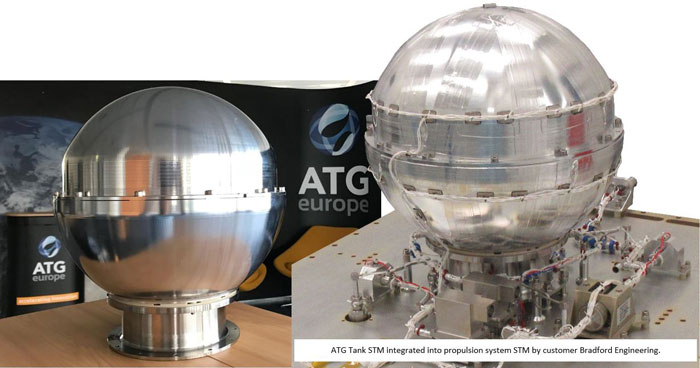

For the Structural Thermal Model (STM) of the P200 platform propulsion, ATG developed, built and delivered an STM of the propellant tank (without propellant holding ability); achieving a predictable structural and thermal behaviour, similar to the flight product, at a fraction of the cost and lead-time.

Individual configurations were developed for the Thermal Model (for the thermal tests) and Structural Model (for the structural tests) based on a modular approach with standard aerospace grade stainless steels and aluminium alloys as well as isolative materials incl. PEEK.

ATG managed the Tank STM manufacturing and after assembly and integration testing delivered it to Bradford Engineering for integration into their propulsion STM.

The Tank STM was developed under a programme of and funded by the European Space Agency. The view expressed herein can in no way be taken to reflect the official opinion of the European Space Agency

The latest developments

Italian Ambassador Giorgio Novello and Italian Commercial Attaché Pina Alivernini join ATG for an exclusive visit to a new cost-effective grid stiffened space structure

Last Wednesday, the 29th of March, His Excellency Mr. Ambassador Giorgio Novello, Italian Ambassador to The...

The first satellite of the IRIDE programme launched – Pathfinder Hawk

Last week, the HEO (Hawk for Earth Observation) Pathfinder microsatellite successfully entered orbit! This marks the...

New Service in Educational Domain Launched!

We are proud to announce the launch of a new domain of services to the European Space Agency (ESA)! Over the years, as...

2023 EFC2 Award for Best in Domain

We are proud to announce that, once again in 2023, our client, the European Space Agency (ESA), has recognized and...

We’re returning to the Space Tech Expo 2024!

Meeting with our experts? Yes! - Exploring business opportunities? Absolutely – Excited for product advancements? Get...

Notice: Provision of Engineering Support Services – Ground Segment and Space Segment Engineering Support for EUSPA

ATG Europe has been awarded a framework contract for the "Provision of support services to the European Union Agency...

Wrapping up a space engineering workshop season: Our latest studies presented are now available online!

Lately, we had the opportunity to attend two leading conferences in the space engineering community, where we...

ATG Europe’s booth drew a crowd at ESTEC Open Day 2024 – Successfully bringing space closer to the public!

Last week, ATG joined the NL Space tent at the ESA ESTEC Open Day, welcoming more than 11,000 enthusiastic visitors!...

Industry Space Days 2024: Showcases Cutting-Edge Innovations and Business Opportunities

Industry Space Days (ISD) has proven to be the place where experts and innovators converge to push boundaries, and ATG...

“The next step is to go to space” – Watch the interview of our success at the JEC Composites Innovation Awards

Earlier this year, ATG Europe was honored to be recognized as the winner in the "Aerospace Category Parts" by JEC for...

The mosaic of ATG Engineering’s Structural Team

The Structural team of ATG Engineering brings different strengths, years of experience, and unique personalities. This...