Get to know Jan Junker and ATG’s Thermal Engineering unique capabilities

We’ve introduced ATG Engineering’s impressive thermal engineering portfolio. But should you choose to partner with us, it’s even better to get to know the key contributors to your projects!

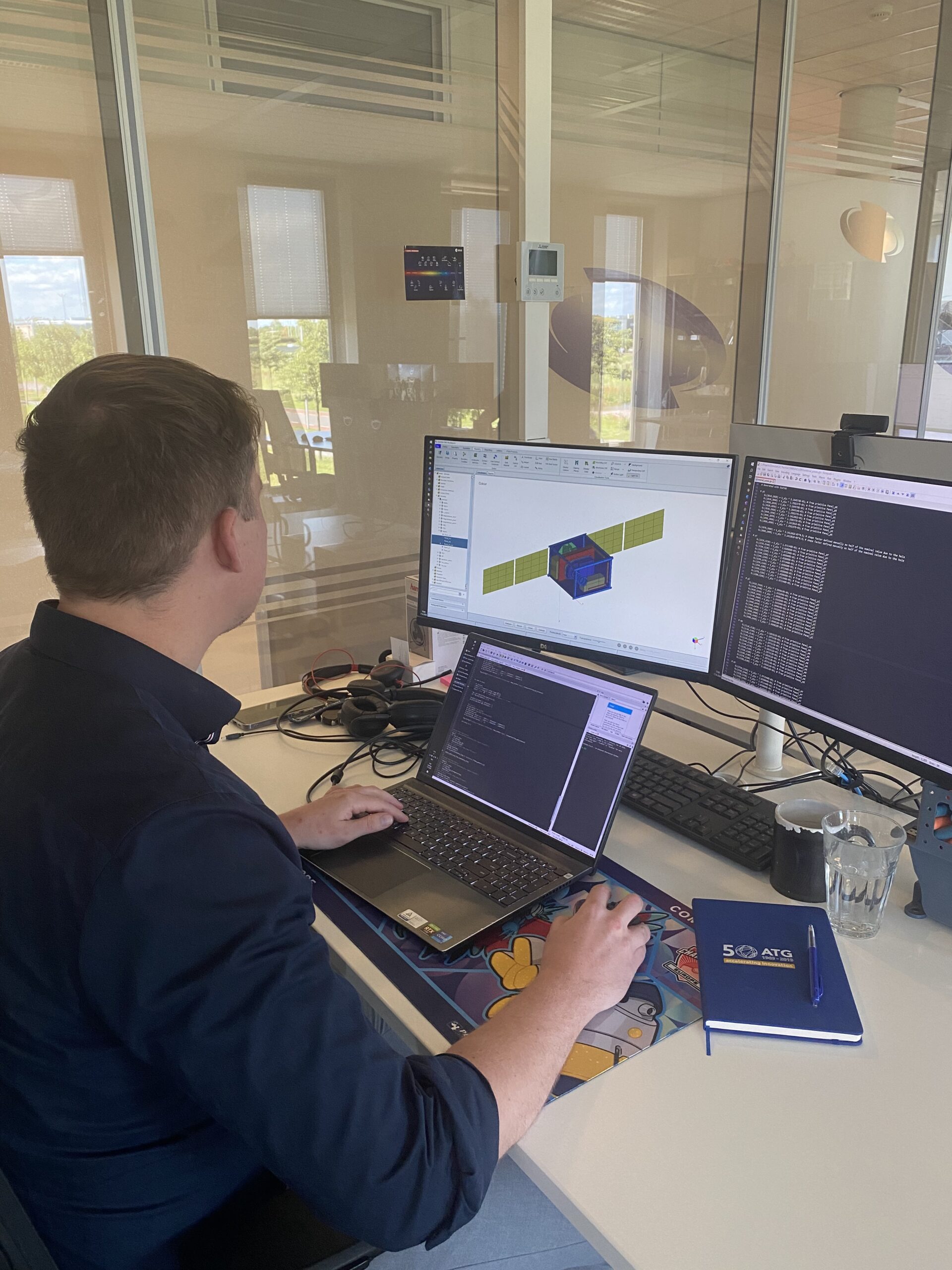

First, let us bring in Jan Junker, one of ATG’s Thermal and Structural Engineers. As he works on both thermal projects and structural analyses and test correlations, he will provide valuable insights into Thermal Engineering and ATG Engineering’s unique capabilities.

The collaborative nature of ATG’s Thermal Engineering

“As a key player driving innovation in the field, ATG Engineering has significantly contributed to collaborative initiatives with proven expertise in thermal system verification and solutions.

In these projects, ATG’s Thermal Engineering interacts with and supports various other teams. As a Thermal Engineer, I integrate data from mission analysis, electronics, and subsystem specialists into my thermal analyses. Besides using these inputs to size the thermal control system, I also produce detailed temperature maps for Structural Engineers’ thermo-mechanical analyses, which are used by Performance Engineers to evaluate optical instrument performance.

The creativity and flexibility of ATG’s Thermal Engineers

“While most spacecraft components have a typical modelling practice to achieve the best technical accuracy, every project we come into is usually at a different stage and requires a lot of creativity and flexibility.

Sometimes we start a project with no previous thermal model existing at all, so we build everything from scratch. This involves digging for reference CAD files, descriptions of materials, data sheets of different units, qualified temperature ranges, and heat dissipation information.

Other times, we join a project already in an advanced phase and get a model that has evolved over years of iteration by other engineers. In this case, we need to update the current model to meet the new requirements while maintaining existing functionalities.”

What makes ATG Engineering’s thermal services and solutions stand out

“We offer efficient and high-quality thermal analysis, design, and verification as an external party. We not only use industry-standard tools like ESATAN and Thermica but have developed our own Python-based tools for detailed and adaptable post-processing and visualization of the analysis results. Specifically in the field of thermo-mechanics, we have developed a suite of tools to support cutting edge thermo-elastic analysis & verification.

To offer even more innovative services, we’ve are also working towards providing our own Thermal hardware products to provide a unique solution to common problems we encounter and to complement our verification engineering services.”

The rewards of working as a Thermal engineer

“The biggest payoff is always seeing the actual hardware and how it all comes together in the end.

So, it’s exciting to support the testing phase. We’ve worked with partners who are focused on building high-performing optical units. However, when it comes to thoroughly testing them in a thermal vacuum chamber and correlating the data, they might still be finding the best approach. So, we help them with the preparation and planning of the tests to maximize the return on these expensive test campaigns. We assist with what to measure, how and where to measure, and then how to correlate the data and validate the models.”

ATG Engineering as a team

“ATG Engineering is a small and close-knit team that values collaboration and knowledge sharing, helping us better estimate and meet project requirements. For instance, we have weekly meetings where one person shares the technical challenges in their current project. We also maintain an internal knowledge base with step-by-step guides for software and best practices in modeling.”