Italian Ambassador Giorgio Novello and Italian Commercial Attaché Pina Alivernini join ATG for an exclusive visit to a new cost-effective grid stiffened space structure

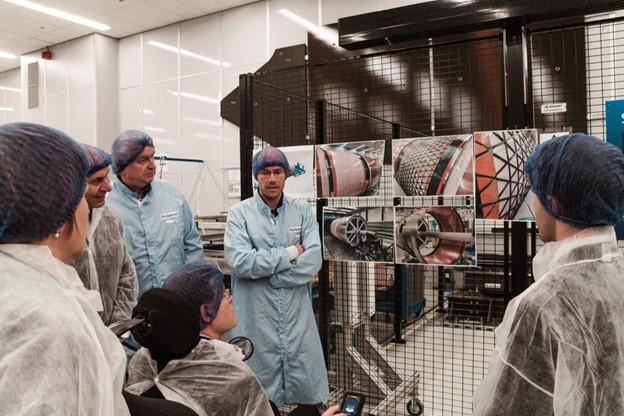

Last Wednesday, the 29th of March, His Excellency Mr. Ambassador Giorgio Novello, Italian Ambassador to The Netherlands, and Pina Alivernini, Commercial Attaché for the Italian Embassy, visited ATG’s ultralight lattice structure. They were accompanied by ATG Europe’s Chief of Operations Massimiliano Mazza and Director of Operations of ATG Engineering Jacob Pasqualotto in the Airborne facility, where the structure is hosted as part of their collaboration.

The cost of space launches is a major contributor to the overall mission cost and the future of space missions, especially the commercial ones, depend massively on its reduction. The implementation of ATG’s patented technology in the development of ultralight interstage structures, in collaboration with Airborne expertise in carbon composite manufacturing, tackles this precise problem. ATG and Airborne work together to implement an efficient architecture at a low manufacturing cost while building products with higher performances.

Massimiliano Mazza (ATG) said “We are immensely proud of our achievements so far and pleased of the continuously recognition of our results by commercial players and institutional parties. The visit of His Excellency Novello is a mutual token of appreciation and friendship between ATG Europe and the Italian Embassy”.

Sandor Woldendorp, Director at Airborne Aerospace, guided the tour through Airborne’s facilities in The Hague, to show the incredible projects ATG and Airborne are developing together in the context of ultralight lattice and grid-stiffened composite structures for launcher vehicles.

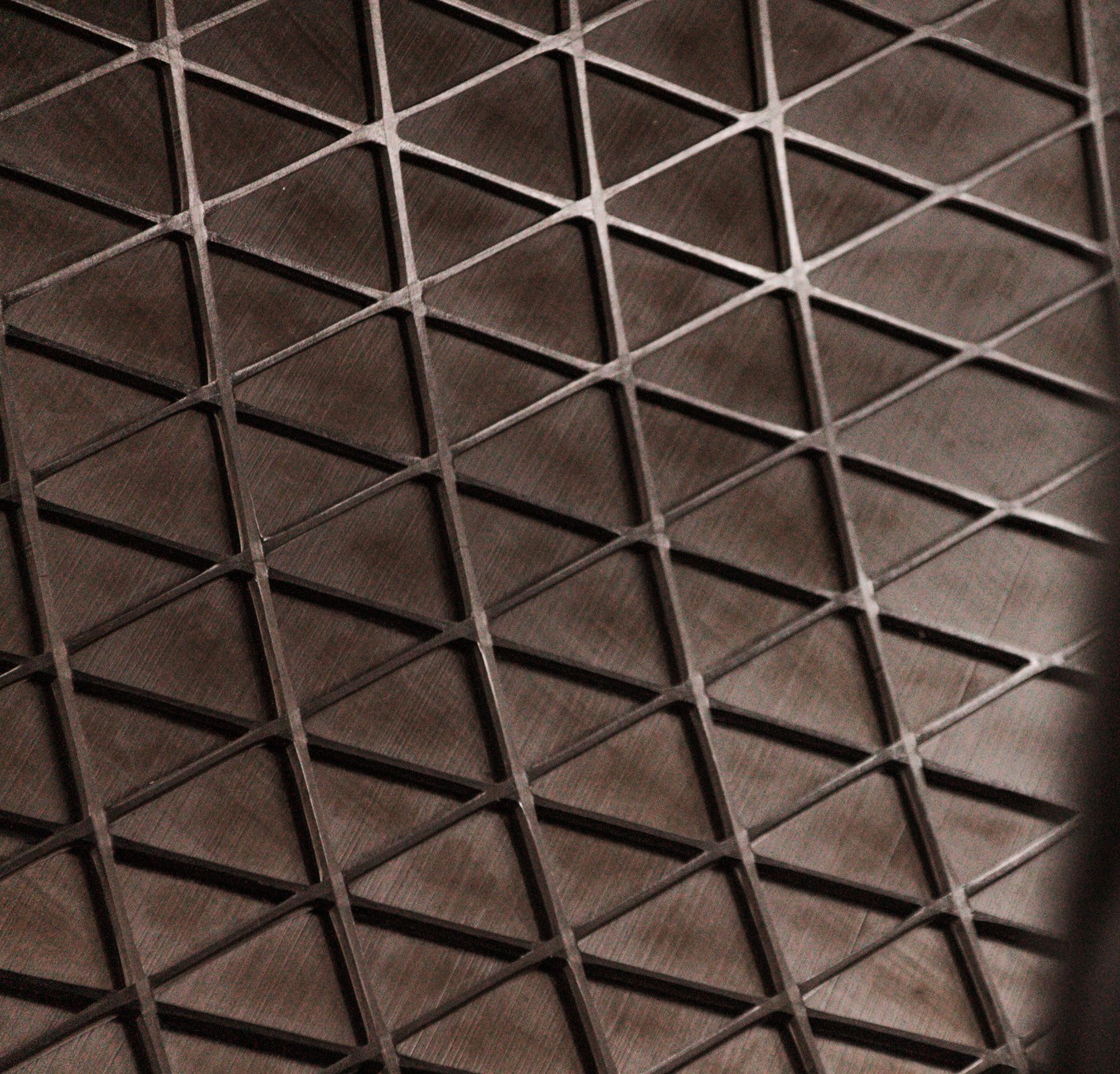

These structures are manufactured through an ATG patented process and can reach high stiffness and strength at a minimum weight. The cost of the structures is comparatively low since everything is produced in a true one-shot process. This efficient process makes these structures an attractive solution for potential customers as it ensures a single layup and curing step which results in a net shape structure.

Only 10 months‘ time to design and produce two light–weight Grid-Stiffened composite launcher inter-stages ? It’s indeed possible to despite the sophisticated products with a patented composite to our customer. These sophisticated products, with a patented composite.

The ultralight structure is indeed a result accomplished thanks to ATG patented process and Airborne facilities and expertise in developing and manufacturing space-grade composite part.

These new structures provide a superior structural efficiency compared to any conventional architecture. This is achieved by placing uninterrupted, uni-directional composite ribs along the main load paths, thus utilising the full strength and stiffness of the composite material.

With this new structure for space vehicles ATG Europe and Airborne confirm to be extraordinary prime actors of the NewSpace sector.

About ATG Europe

ATG can count on an international team, made of professionals of 32 different nationalities, through which it has been providing to its customers over 50 years of value-added engineering services, 3D photo-realistic images and animations, VR&AR experiences, tech products and a praised management support at the highest possible standard. ATG truly values every culture brought by its people as they strengthen its core and make it more aware in addressing new markets and business environments. ATG serves institutional and industrial players of the big science sector, and especially the space and nuclear fusion ones, complementing and enhancing their capabilities, performances, and competitiveness and driving them beyond their ambitions.

This is how ATG is accelerating innovation.

About AIRBORNE

Airborne is leading the way in the engineering and manufacturing of composite panels for aircraft, satellites and launchers. Through industrialisation, digitalised automation and applying different production process technologies, we are making aerospace components more affordable for our customers and partners.

Airborne is the European market leader in the manufacturing of solar-array substrate panels and has delivered over 400 state-of-the-art solar-array substrates to several paramount institutional as well as commercial satellites. With over 25 years of expertise and qualifications, Airborne also grows in the manufacturing of sandwich panels for satellite platforms and instrument structures.

Production automation is applied for satellite constellations as well as for micro-launchers, where smart robotic systems enable affordability as well as higher volume production. Airborne is committed to be a key partner to the NewSpace system integrators.

For more information please contact:

ATG Communications

Space Business Park

Huygensstraat 34

2201 DK Noordwijk (NL)communication@atg-europe.com

T: +31 (0)71 579 5500