ICARUS

Background

Training for assembly procedures mostly makes use of physical models of the actual hardware. Because of this approach, cost of training is generally high and the level of flexibility to accommodate changes in configurations is low. Furthermore, as physical models are manufactured at discrete moments in the development program, the availability of these models and therefore the actual moment of training is predefined and fixed. Moreover, in a commercial space environment where recurrence in hardware production and integration is to be expected, it is essential to retain knowledge of applied processes and procedures in these fields.

When using an immersive tool to capture the knowledge on how to apply these procedures, that data can at a later stage unambiguously be transferred to new project participants or new employees. This has the added benefit of lowering the need for a certain skill level in the labour force which inevitably leads to cost reduction.

ICARUS

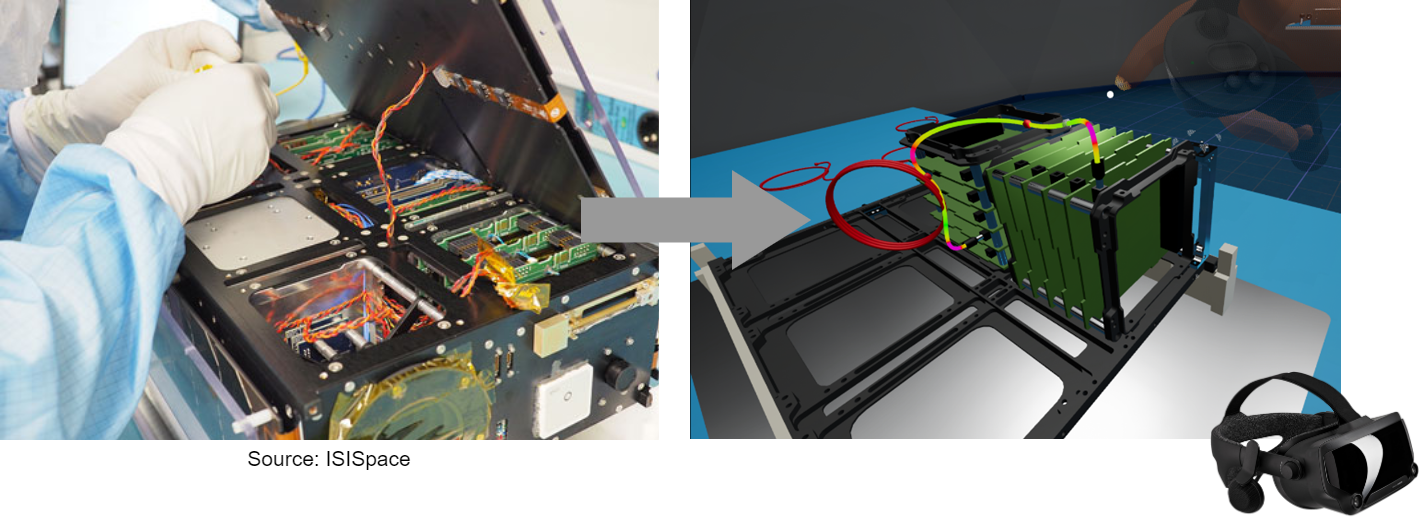

Because of the above, ATG Europe is developing ICARUS, a Virtual Reality tool aimed at training of mechanical assembly and integration processes.

ICARUS will offer the following key benefits to its users:

– Train mechanical assembly and integration processes in a virtual environment at any moment in time, either guided (instructions) or non-guided (trying-out what is possible). This will provide more flexibility in the timing of the training and much lower cost by not using actual physical flight hardware for training purposes.

– Improve knowledge retention of the recurring operations through a virtual representation of the customers guidelines and best practices. Thereby enabling an easier transfer of knowledge to new employees, increasing their productivity, and lowering the initial skill level required.

– Train launcher integration using a virtual representation of the satellite, to be carried out remotely in a collaborative digital environment. Thereby saving valuable time of all parties involved and providing more flexibility in the timing of this integration testing.

Thus, ICARUS will enable users to improve the efficiently, increase the flexibility and decrease the risk of their assembly and integration processes considerably.

Towards ICARUS 1.0

Most value coming from a VR training tool is added to programs which are recurring in nature, in other words where assembly is a well-defined (documented) process which is passed on through the company or a program over time. In the space domain this is evidently applicable to CubeSat programs more than to (one-off) developments of large science or earth observation satellites. For this reason, ATG Europe has teamed up with ISISpace, one of the leading companies in the fast-growing small satellite market. ISISpace provides the best practices for assembly and integration, initial models to incorporate into ICARUS, and serves as a launching customer. For the initial version of ICARUS, the following key features are foreseen:

1. Simulate generic assembly processes, such as manual cable routing, applying epoxy and using precision tools such as screwdrivers and tweezers, in a realistic manner

2. Enable users to easily incorporate their own model geometries

3. Enable users to easily incorporate their own assembly and integration procedures and training scenarios

First Steps Concluded

As a first but important step in the ICARUS development we now incorporated the main generic processes, as shown in the video below. This allows users to freely practice these activities on preloaded models and without proper instructions.

Next Steps

Our next milestone is reached when we are able to provide our users the flexibility of uploading their own models and add instructions on how to assemble these into a system. Stay tuned for updates later in the year!

Are you interested in the benefits which ICARUS could offer your company?

Want to stay up to date with our latest developments?